Revolutionizing Construction: Parametric Design Meets 3D Printing Arms

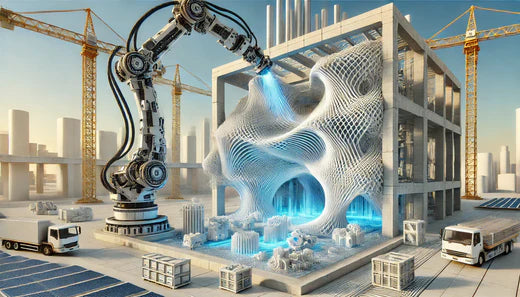

The world of construction is undergoing a profound transformation, driven by cutting-edge technologies that promise to redefine how we build and design our spaces. At the forefront of this revolution is parametric 3D printing, paired with robotic arms. This dynamic duo is unlocking new possibilities for customization, efficiency, and sustainability in construction, setting a new standard for the industry.

What Is Parametric Design?

Parametric design is a method of creating architectural and structural elements based on mathematical algorithms. By adjusting input parameters, designers can generate complex and intricate forms that are impossible or highly labor-intensive to achieve with traditional methods. Think undulating walls, organic structures, and flowing geometries—all tailored to specific needs and contexts.

When combined with 3D printing, parametric design offers an unprecedented level of precision and flexibility. By programming a set of rules, designers can create bespoke designs that adapt to functional requirements, aesthetic preferences, and environmental considerations.

Why Use Robotic Arms for 3D Printing?

Robotic arms enhance 3D printing capabilities by providing greater reach, precision, and adaptability. Unlike traditional 3D printers with limited build volumes, robotic arms can move freely across multiple axes, enabling the construction of large-scale structures without being confined to a box. This flexibility allows:

-

Non-Planar Printing: Print complex geometries that go beyond flat, horizontal layers.

-

Larger Build Areas: Create structures on a scale that traditional 3D printers can’t achieve.

-

Seamless Integration: Print directly on-site, reducing transportation costs and delays.

Key Advantages of Parametric 3D Printing with Robotic Arms

-

Sustainability Robotic 3D printing supports sustainable practices by minimizing material waste. Parametric design ensures that each element uses only the materials necessary, reducing excess and promoting efficiency. Additionally, the ability to use recycled materials like PETG or concrete aggregates further enhances its eco-friendliness.

-

Customization at Scale Traditional construction often relies on standardized elements, limiting creativity and adaptability. Parametric 3D printing allows for mass customization, enabling builders to create unique designs for every project—whether it's a flowing façade or an acoustic panel tailored to a specific room.

-

Time and Cost Efficiency Automated fabrication eliminates many of the labor-intensive processes associated with traditional construction. Robotic arms can work around the clock, maintaining precision and consistency while dramatically cutting down on build times.

-

Enhanced Design Complexity Intricate designs that were once the domain of handcrafting or expensive molds can now be realized quickly and affordably. This opens up new opportunities for architectural experimentation and innovation.

Applications in Construction

Parametric 3D printing with robotic arms is finding applications across various sectors:

-

Architectural Features: Unique façades, partitions, and decorative elements that enhance building aesthetics.

-

Structural Components: Load-bearing walls, columns, and beams tailored to specific engineering requirements.

-

Interior Design: Custom furniture, lighting fixtures, and acoustic panels that blend functionality with artistic expression.

-

Sustainable Housing: Efficiently constructed, eco-friendly homes that address the global housing crisis.

Challenges and Opportunities

While the potential is enormous, parametric 3D printing in construction faces challenges such as:

-

Material Development: Advancing materials that are strong, lightweight, and sustainable.

-

Regulatory Approvals: Ensuring compliance with building codes and standards.

-

Skill Gaps: Training professionals to work with these new technologies.

However, each challenge represents an opportunity for innovation and growth. As the technology matures, we can expect to see broader adoption and a significant shift in how we approach construction.

Looking Ahead

The fusion of parametric design and robotic 3D printing arms is more than a technological innovation; it’s a paradigm shift. By embracing this approach, we can build smarter, greener, and more beautiful structures—paving the way for a future where construction is not just a necessity, but a form of art.

As leaders in this space, we are committed to pushing the boundaries of what’s possible, using these technologies to create designs that inspire and endure. Stay tuned for more updates on how we’re transforming the construction landscape, one layer at a time.

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.